Oil leaks can also reduce oil pressure, and oil pressure is essential for keeping tension on the timing belt. Oil LeakĪn oil leak can cause a timing belt to slip off its track if the oil gets in between the teeth of the belt. If you notice any abnormal vibrations in the vehicle, it’s best to get it checked out immediately before the timing belt slips off or breaks completely. If your engine is shaking or vibrating the car, it could result from the timing belt wearing down or coming off its tracks. Newer cars sometimes have a warning system to indicate that your engine is running at a reduced power. If your engine is misfiring or has a sour air/fuel mixture, it could be a sign of an out-of-sync system that will cause your engine to run less efficiently. While overheating is not always a timing belt issue, you should always take it very seriously. It’s not wise to drive on an engine that is overheating, and you won’t be able to for long. OverheatingĪ worn belt that’s out of sync can cause the engine to overheat, further damaging the engine and its components. Ticking noises in the engine are closely related to oil pressure as well, so if you hear this sound consistently, it’s best to get it checked out. Engine Ticking NoiseĪ ticking noise under the hood could signify an out-of-sync piston hitting a valve at the wrong time or something else wrong with the camshaft system. The sound will usually be high-pitched and quite noticeable. If your timing belt is wearing down, the grooves in the belt could make uncomfortable noises by rubbing against the engine during operation. This is a common symptom of worn engine belts. If your car isn’t starting, it’s more than likely due to something other than the timing belt.

That said, timing belts tend to break when the engine is running, and there are a variety of reasons that your car might not start. If your engine is having trouble starting, it could indicate that the timing belt is out of sync with the valves and pistons and won’t move properly.

Let’s examine these symptoms closer: Starter Issue Here’s a list of signs that it might be time to replace your timing belt: It could lead to broken or bent valves, damage to cylinder heads and camshafts, piston-cylinder wall damage, or total engine failure. You should replace your timing belt between 60,000 to 100,000 miles (96,561 to 160,934 kilometers) or when your check engine light comes on due to its damage.ĭelaying the repair or replacement of a timing belt can be increasingly costly.

#SERPENTINE VS TIMING BELT MANUAL#

Read: Is CVT More Efficient Than Manual Transmission? When Should I Replace My Timing Belt? It also doesn’t require a complete engine cool down for replacement and is considered a faster repair job. Serpentine belts are far less expensive repairs because the part is easily located on the engine and isn’t costly to buy from a parts store. Timing belts are much more expensive because they are inside the engine, and some repair shops wait a whole day for the engine to cool down before opening it for any work, even if to replace a worn belt. Failing serpentine belts cause all the engine accessories to lose power, which will cause the engine to overheat. A failing timing belt can cause the pistons, valves, and cylinder heads to go out of sync and collide. When the timing or serpentine belt fails, vital engine components quit working. What Happens When the Timing or Serpentine Belts Fail? Most multiple belt systems are older, used on larger vehicles, and consume more space under the hood.

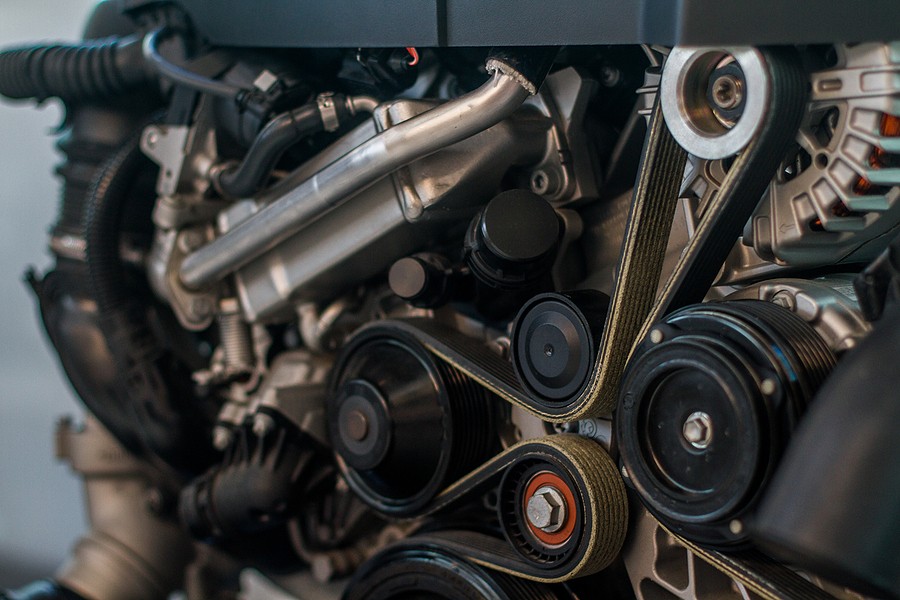

The flip side is that if a belt slips or goes bad, it only affects one accessory instead of a single belt affecting all of them. There’s a higher chance of multiple belts slipping due to lower tension and reduced belt life. Some older vehicles use multiple serpentine belts instead of one long belt. Read: Tensioner Pulley Replacement Cost Two Belts vs. They withstand heavy use and very high temperatures most of the time. They’re called “serpentine” because of how they snake through the engine accessories. Serpentine belts are long, black, thin, and made of rubber. Serpentine belts constantly rotate when the car is running, using a pulley system with a tensioner to move rotational power when being spun by the engine’s crankshaft. It coils itself around the engine accessories and keeps moving to transport power to them all at once. The serpentine belt connects the engine crankshaft to the parts of the engine that maintain the system.

0 kommentar(er)

0 kommentar(er)